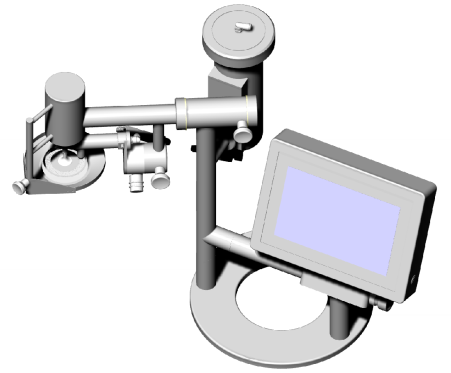

JetCutter lab equipment

JetCutter technology has been developed around the turn of the millennium and brought to market maturity. Due to its unique combination of high throughput and true mechanical portioning of the

fluid, it allows a variety of new possibilities, e.g. high loading with solids or water-insoluble substances.

The mechanical cut makes the sphere formation largely independent of fluid properties and thus enables high-quality products also based on biopolymers, which are often less tightly specified.

JetCutting thus allows the production of products with a narrow particle size distribution even with high viscosity of the fluids and with high throughput.

To enable cutomers evaluating JetCttuing for their individual task in encapsulation and bead making, we offer very versatile lab machines that are easy to operate.

Those machines have a standard layout but are customised to the individual needs by chosing the right cutting tools, nozzles, and accessories to meet the customers requirements.

To choose the right configuration for the JetCutter, we need to know the nature of the fluid that ought to be processed to droplets (e.g. viscosity range), the droplet size (range) aimed at, the batch size to be processed, etc.

Please get in contact with us for any inquiry related to the JetCutter! The use might be restricted for certain areas of application due to exclusive arrangements geniaLab has!

Our current price list is also available on request!